EMISSIONS

GRI Standards

| GRI 305: Emissions | Section/Comments | |

|---|---|---|

| GRI 103-1 | Management approach: Explanation of the material topic and its boundary |

Material aspects & scope |

| GRI 103-2 | Management approach: The management approach and its components | |

| GRI 103-3 | Management approach: Evaluation of the management approach | |

| GRI 305-1 | Direct (Scope 1) GHG emissions | 2777 MT of CO2 eq |

| GRI 305-2 | Energy indirect (Scope 2) GHG emissions | 36633 MT of CO2 eq |

| GRI 305-3 | Other indirect (Scope 3) GHG emissions |

This year, we have partnered with subject-matter experts to evaluate our detailed Scope 3 inventorisation to ensure completeness and correctness of the total emissions. |

| GRI 305-4 | GHG emissions intensity | 0.11(MT of emissions/MT of production) |

| GRI 305-5 | Reduction of GHG emissions | Green House Gas emissions |

| GRI 305-6 | Emissions of ozone-depleting substances (ODS) |

Air emissions |

| GRI 305-7 | Nitrogen oxides (NOX), sulfur oxides (SOX), and other significant air emissions |

|

Green House Gas (GHG) Emissions

At KNPL, we understand our responsibility of tackling climate change and therefore set over-arching targets to reduce our carbon footprint through our operations, sensitise our value chain on the impact and have Board-level oversight to mitigate the forecasted risks. In addition to GHG emissions, we also track and curb other significant air emissions caused due to our operations.

| Types of GHG Emissions accounted | Activities | Scope of Data |

|---|---|---|

| Scope 1 GHG Emissions: Direct GHG Emissions |

|

KNPL India operations |

| Scope 2 GHG Emissions: Indirect GHG Emissions |

|

KNPL India operations |

In FY21-22, we have partnered with subject-matter experts to evaluate our detailed Scope

3 inventorisation to ensure completeness and correctness of the total emissions. We have

identified the relevant categories applicable to our organisation:

Category 1: Purchased Goods and Services

Category 2: Capital Goods

Category 3: Fuel- and Energy-Related Activities Not Included in Scope 1 or Scope 2

Category 4: Upstream Transportation and Distribution

Category 5: Waste Generated in Operations

Category 6: Business Travel

Category 7: Employee Commuting

Category 8: Upstream Leased Assets

Category 9: Downstream Transportation and Distribution

Category 10: Processing of Sold Products Category 11: Use of Sold Products

GHG Emission Intensity - Methodology Followed

The GHG emissions are estimated based on guidelines emission Intensity by 5% year-on-year. defined in the World Resource Institute’s (WRI) Greenhouse Gas (GHG) Protocol and CEA (Central Electrical Authority) database. Relevant industry standard emission factors and emission factors prescribed by the Intergovernmental Panel on Climate Change (IPCC) have been used appropriately to determine GHG emissions.

| Financial Year | Scope 1 | Scope 2 | Total Emissions (CO2 eq. in MT) |

Emission (in MT) per MT of Production |

|---|---|---|---|---|

| 2015-16 | 6886 | 36532 | 43418 | 0.16 |

| 2016-17 | 6449 | 38273 | 44722 | 0.16 |

| 2017-18 | 5461 | 40228 | 45689 | 0.15 |

| 2018-19 | 4111 | 40672 | 44783 | 0.14 |

| 2019-20 | 1419 | 36721 | 38140 | 0.13 |

| 2020-21 | 1087 | 31969 | 33056 | 0.11 |

| 2021-22 | 2777 | 36633 | 39410 | 0.11 |

- Increase in absolute emissions is due to the incorporation of 2 additional Manufacturing facilities – Marpol (Goa) and Perma (Sarigam) in our scope

- Method of Calculation: GHG Emission Intensity is the ratio of GHG emissions (Scope 1 + Scope 2) to Total Production of Finished Goods during specified period

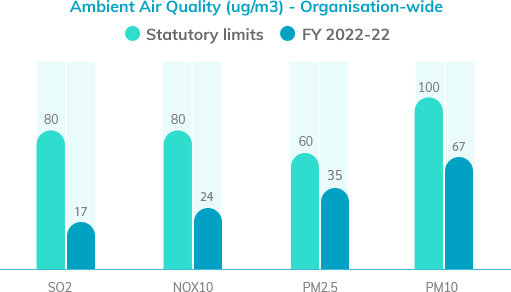

Air Emission

The emissions and air quality levels are periodically monitored by external

agencies. All our manufacturing sites have requisite controls and measures

in place to manage these emissions and ensure the levels well within the

prescribed limits. We ensure compliance with limits recommended in the

National Ambient Air Quality Standards (NAAQS) 2009.

In addition to conventional air pollution control devices like Air

Handling Units (AHUs), Dust Collectors, Fume Extractors, and Forced Draft

Ventilation systems, we have also installed Scrubbers in the resin area and

Cyclone Separator in solid fuel boilers to reduce Suspended Particulate

Matter (SPM). Our vents are equipped with Activated carbon filter to filter

air emissions before discharge into ambient atmosphere. For continuous

monitoring, provision of online stack monitoring systems are made to ensure

compliance with permissible limits

Reduction of GHG emissions

- Increasing renewable portfolio – Solar and Wind Power, Cleaner Fuels

- Consistent tracking and monitoring of our GHG emissions through customised GHG Accounting Tool Dedicated EHS and Climate Change Framework

- Detailed Scope 3 inventorisation

- Establish GHG reduction targets in line with Science Based Target initiative

During the reporting period, we responded to CDP questionnaire for Climate change and secured a rating of C (Awareness: Knowledge of impacts on, and of, climate issues). As a responsible organisation, we aim to improve this rating in coming years.

Improved Air Quality Diligent monitoring

- Ambient air quality, stack emissions, VOC levels

- Deployment of advanced air pollution control devices

- Adoption of refrigerant gas with zero ozone depleting potential

Emissions of Ozone-Depleting Substances (ODS)

In regards to ODS emissions, ozone depleting R-22 refrigerant is in use only in limited quantities at old facilities for work area air conditioning; while R-134a and R-407c, refrigerant gas with zero ozone depleting potential is majorly used organisation-wide.