ENERGY

GRI Standards

| GRI 302: Energy | Sections/Comments | |

|---|---|---|

| GRI 103-1 | Management approach: Explanation of the material topic and its boundary | |

| GRI 103-2 | Management approach: The management approach and its components | Material Aspects & Scope |

| GRI 103-3 | Management approach: Evaluation of the management approach | |

| GRI 302-1 | Energy consumption within the organization | 444907 GJ

Electricity - KNPL consumption: 226530 GJ - 31% through renewable sources - Heat & steam - Steam consumption: 17,293 MT - Heat consumption: 1,93,807 Lac Kcal - 100% through renewable sources |

| GRI 302-3 | Energy intensity | Energy Intensity: 1.24 GJ/KL of FG

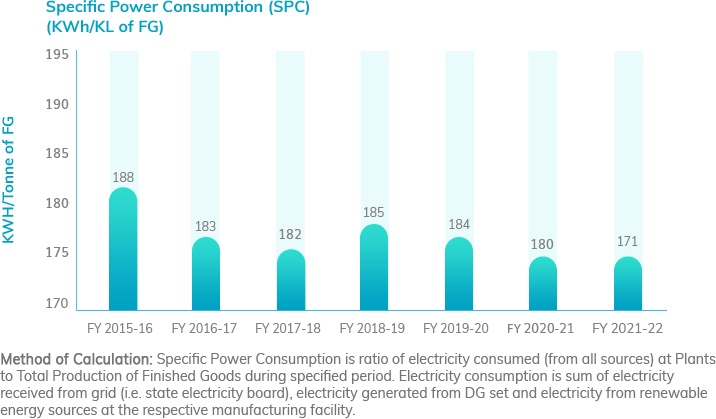

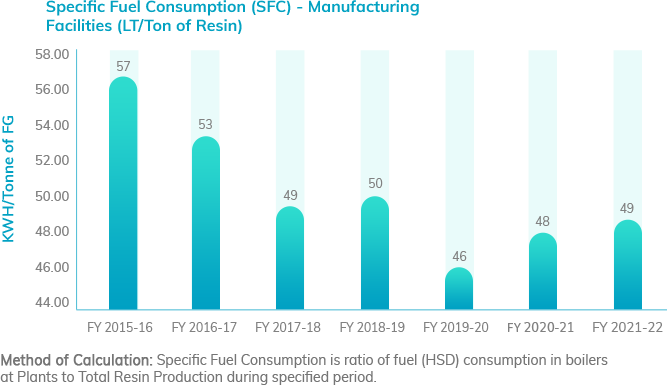

Manufacturing Facilities Sp. Power Consumption: 171 KWH/KL of FG Sp. Fuel consumption: 49 Lt/Ton of Resin |

| GRI 302-4 | Reduction of energy consumption | Energy consumption |

| GRI 302-5 | Energy consumption |

Manufacturing Facilities

Rain Water Used in Process – 8659 KL Water Intensity - Specific Water Consumption = 1.16 KL/KL of FG |

Planning for the Future

Focussed approach and consistent work along the lines of “Energy security” theme has helped us reduce our energy cost Y-o-Y; at the same time adopt environment-friendly technologies thereby reducing our Carbon footprint. In the current year, our focus was to improve the efficiency of systems at plants. Replacement of conventional pumps/ motors with energy efficient options, conversion of motors starters to star / delta based on loading pattern, installation of cyclic timers on mixers, descaling of water jackets were undertaken thereby reducing overall power consumption which led to improvement of energy efficiency.

Electricity Consumption

At KNPL, progress in energy management is measured through key indicators of specific power consumption, specific fuel consumption and percentage of renewable energy.

| Sources of Electricity | Electricity (in MWH) |

|---|---|

| Grid energy | 44,782 |

| Diesel generator set | 1,180 |

| Wind energy (sourced through grid) | 6,663 |

| Solar energy | 4,159 |

| Biomass-based electricity | 1,940 |

| Total electricity consumed | 58,724 |

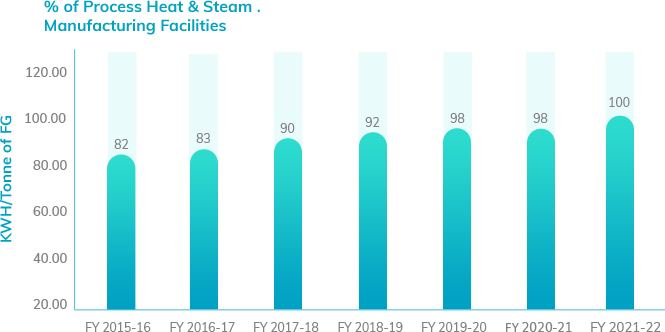

Energy is also used in the form of steam and heat in our manufacturing processes. Most of the steam and heat requirements are being met through bio fuel and biomass based solid fuel boiler.

| Heat & steam generation through a biomass-based boiler | |

|---|---|

| Total steam consumption | 17293 MT |

| Total heat consumption | 1,93,807 Lac Kcal |

Specific Power Consumption

Specific Fuel Consumption

Energy Intensity

In FY 2021-22, we consumed 4,44,907 GJ of energy within the organisation, while our overall energy intensity was 1.24 GJ/ KL of FG.

Method of Calculation:

Energy Intensity is ratio of Total energy (Fuel + Power + Heat and Steam) consumed within factory premises organisation-wide (Manufacturing facilities, R&D centre and Head Office) to Total Production of Finished Goods during specified period.

Reduction of energy consumption

At KNPL we have focussed approach and consistent work along the lines of “Energy security” theme has helped us reduce our energy cost Y-o-Y; at the same time adopt environment-friendly technologies thereby reducing our Carbon footprint. In the current year, our focus was to improve the efficiency of systems at plants.

Replacement of conventional pumps/ motors with energy efficient options, conversion of motors starters to star / delta based on loading pattern, installation of cyclic timers on mixers, descaling of water jackets were undertaken thereby reducing overall power consumption which led to improvement of energy efficiency.

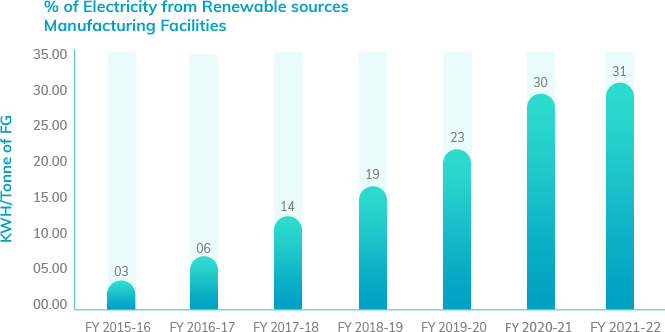

We have achieved a 9% reduction Specific Power Consumption (Manufacturing facilities) since FY 2015-16.

Diversification of Energy-mix

- Solar Capacity augmentation

We have gone with two-pronged approach for solar capacity augmentation wherein we plan to replace hazardous asbestos roof sheets with Galvanised colour coated sheets and subsequently add on solar power panels.

Solar rooftop capacity addition of 1.2 MW at Bawal Solar rooftop capacity addition of 0.6 MW at Jainpur Our current solar power capacity stands at 5.3 MW, and through above implementation we plan to increase the solar power capacity by 7.1 MW.

- Captive Wind Power augmentation

Captive wind turbine at Hosur of 4.2 MW

- Alternate power sourcing

Group Captive Power sourcing capacity of 5.7 MW at Jainpur plant Third-party Power sourcing of ~1.25 MW at Lote By FY 2022-23, we aim to source 41% of our total energy consumption through renewable energy sources.

Renewable Energy:

We constantly search for alternate sources to increase our share for green-energy and accordingly plan our initiatives based on the feasibility and applicability. This in turn allows our facilities to be increasingly self-reliant in their energy needs, and thereby reduce the carbon footprint. In FY 2021-22, the total renewable energy consumed was 2,31,112 GJ which accounts to 52% of our total energy consumption

- Heat & Steam generation through Biomass based Boiler

In FY21-22, our Total steam consumption was 17,293 (MT), however our Total heat consumption was 1,93,807 (Lakh Kcal).

- Other Initiatives :

Carbon Neutrality Project During the reporting period, the following Carbon Neutrality projects were commissioned which enabled us to further increase our green footprint in the overall energy mix. Increase in green power quantum through 3rd party sourcing at Hosur plant Increase in quantum through Group captive wind power at Hosur plant Switching to Piped Natural Gas at Bawal which is a clean and environment friendly fuel.

Renewable Group Captive at Jainpur Energy cost is a major contributor in an overall operating cost of a manufacturing plant. “Group captive” offers dual benefits - cost optimisation and increase in green power. “Group Captive” mode is one of the OPEN ACCESS arrangements, wherein we can purchase power at lower tariff as compared to State Electricity Board tariff. In order to reap the benefits of the same, we have executed a Power Purchase Agreement (PPA) and a Shareholders Agreement (SHA) with one of the reputed developers. Under this arrangement, we have tied up for 5.75 MW solar power sourcing equivalent to 6.7 Lac units a month. Through this partnership, we aim to achieve a cost savings of `190 Lacs.