Kansai Nerolac

The Story Till Date

Energy

GRI Standards

| GRI 302: Energy | Sections/Comments | |

|---|---|---|

| GRI 103-1 | Management approach: Explanation of the material topic and its boundary | |

| GRI 103-2 | Management approach: The management approach and its components | |

| GRI 103-3 | Management approach: Evaluation of the management approach | |

| GRI 302-1 | Energy consumption within the organization | Energy Consumption Table |

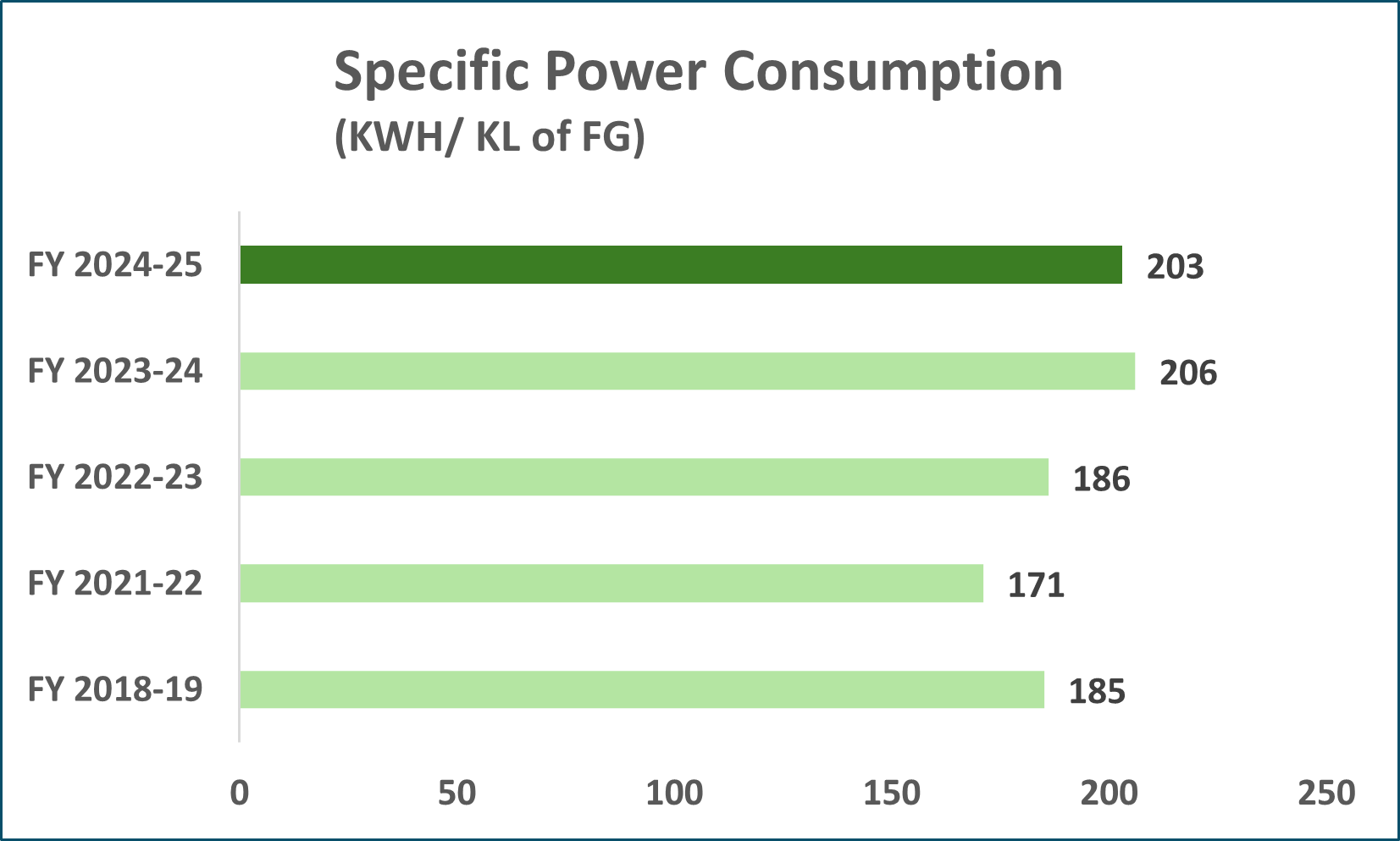

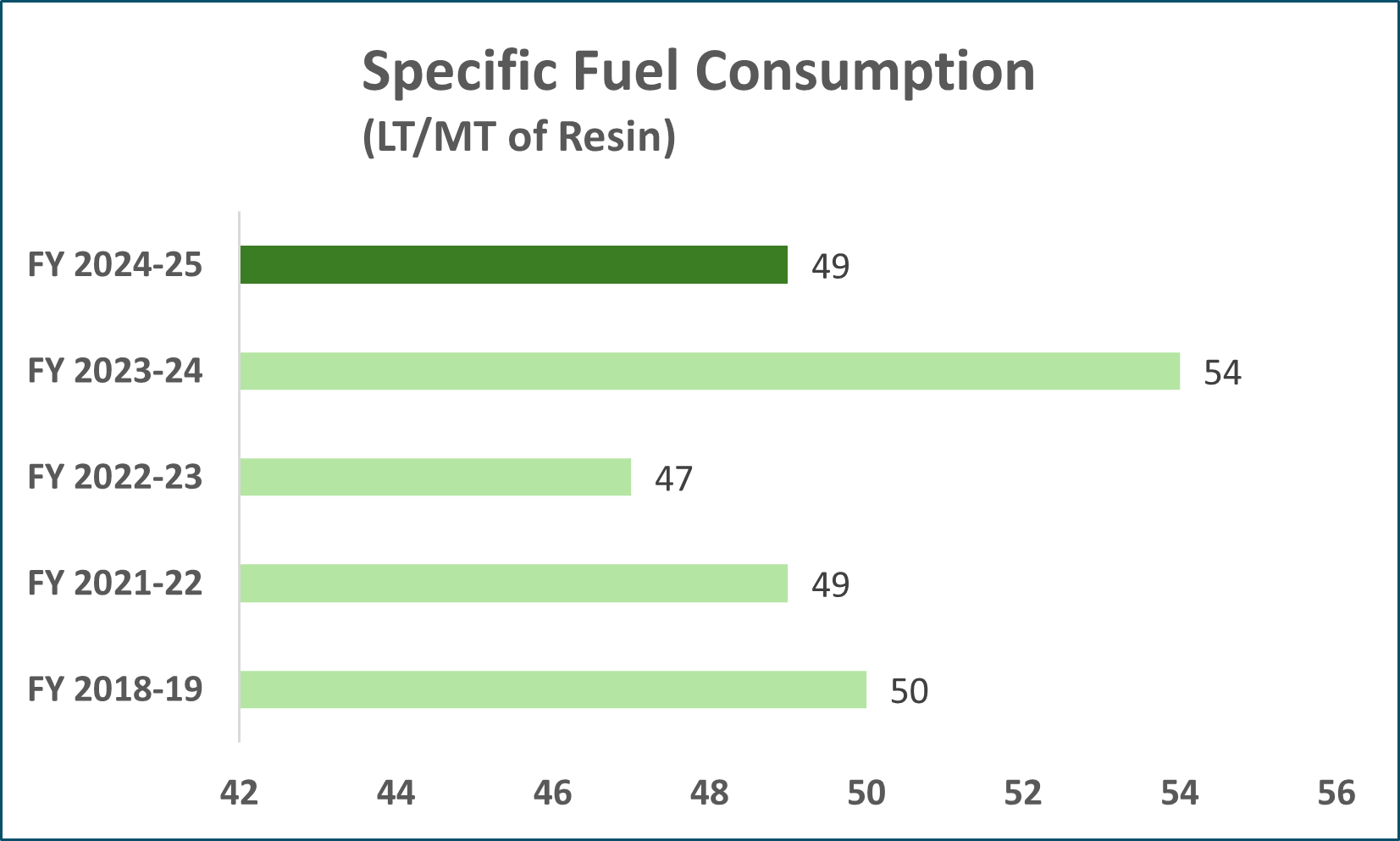

| GRI 302-3 | Energy intensity | Energy Intensity: 1.43 GJ/KL of FG Sp. Power Consumption: Manufacturing Facilities 206 KWH/KL of FG Sp. Fuel Consumption: Manufacturing Facilities 54 LT/MT of Resin |

| GRI 302-4 | Reduction of energy consumption | Sp. Power Consumption: Manufacturing Facilities 203 KWH/KL of FG Sp. Fuel consumption: Manufacturing Facilities 49 Lt/MT of Resin production |

| GRI 302-5 | Reductions in energy requirements of products and services | KNPL actively explores and adopts environmentally friendly options like renewable energy sources like solar and wind power. By integrating renewable energy into its operations, KNPL decreases its reliance on fossil fuels and contributes to the overall decarbonisation of the energy sector. |

Planning for the Future

We are committed to steadily advancing towards achieving our RE 70 targets on a Company-wide scale.

- We plan to have all our plants, Energy Management Systems certified through ISO 50001, an international standard which certifies our commitment towards energy performance and sustainability. Currently 3 of our manufacturing facilities are certified with ISO 50001 Certification.

- We aim to gradually adopt new concepts and technologies which further lead to energy conservation and increased energy efficiency

- We have windmill installations across the states of Maharashtra and Tamil Nadu.

- We have recently commissioned 2100 KW capacity Wind turbine at our Sayakha Plant. With this, our Captive windmill capacity have increased to 8400 KW.

- Commissioning work is in progress for 3000 KW offsite Captive Solar farm in the district of Yavatmal in Maharashtra which shall cater to power requirements at our Lote Plant.

ENERGY CONSUMPTION

At KNPL, progress in energy management is measured through key indicators of specific power consumption, specific fuel consumption and percentage of renewable energy.

| Parameter | FY 24-25 |

|---|---|

| Renewable Sources | |

| Total Electricity Consumption (A) | 1,04,076 GJ |

| Total Fuel Consumption (B) | 11,307 GJ |

| Energy Consumption Through other sources (C) | 1,24,968 GJ |

| Total Energy Consumption through Renewable Sources (A+B+C) | 2,40,450 GJ |

| Non-Renewable Sources | |

| Total Electricity Consumption (D) | 1,72,067 GJ |

| Total Fuel Consumption (E) | 1,19,357 GJ |

| Energy Consumption Through other sources (F) | 0 |

| Total Energy Consumption through Non-Renewable Sources (D+E+F) | 2,91,424 GJ |

| Total Energy Consumption (A+B+C+D+E+F) | 5,31,874 GJ |

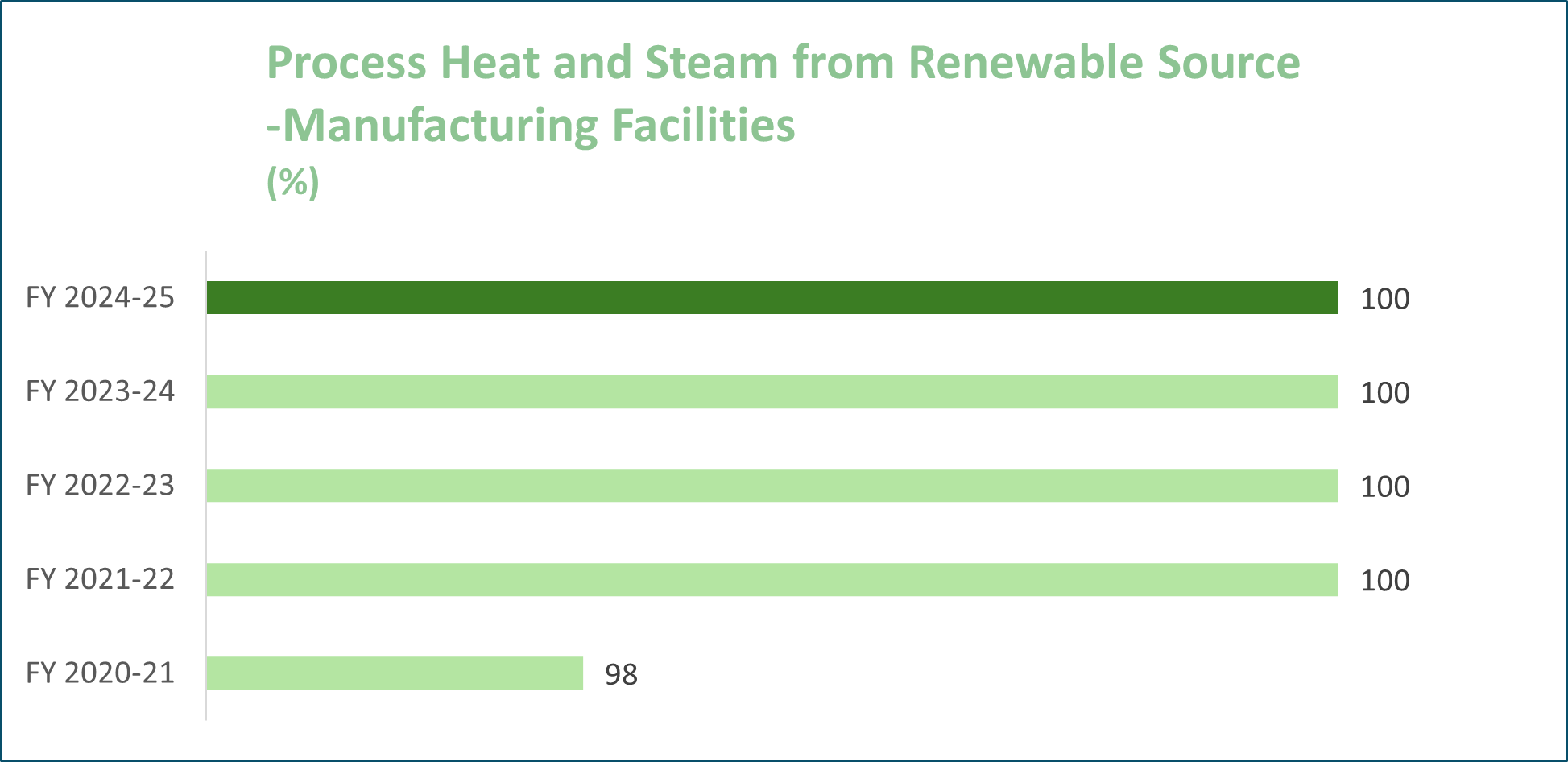

Energy is also used in the form of steam and heat in our manufacturing processes. Most of the steam and heat requirements are being met through biofuel and biomass based solid fuel boiler.

Specific Power Consumption

|

Method of Calculation:

Specific Power Consumption is ratio of Electricity Consumed (from all sources) at Plants to Total Production of Finished

Goods during Specified Period. Electricity consumption is sum of electricity received from grid (i.e. state electricity board), electricity generated

from DG set and electricity from renewable energy sources at respective manufacturing facilities.

Specific Fuel Consumption

|

METHOD OF CALCULATION- Specific Fuel Consumption is ratio of Fuel Consumption in Boilers at Plants to Total Resin Production during a Specified Period.

Energy Intensity

In FY 2024-25, we consumed 5,31,874 GJ of energy within the Company, with an overall energy intensity of 1.44 GJ/KL of finished goods (FG).

Method of Calculation:

Energy Intensity is ratio of Total energy (Fuel + Power + Heat and Steam) consumed within factory premises organisation-wide (Manufacturing facilities, R&D centre and Head Office) to Total Production of Finished Goods during specified period.

Reduction of energy consumption

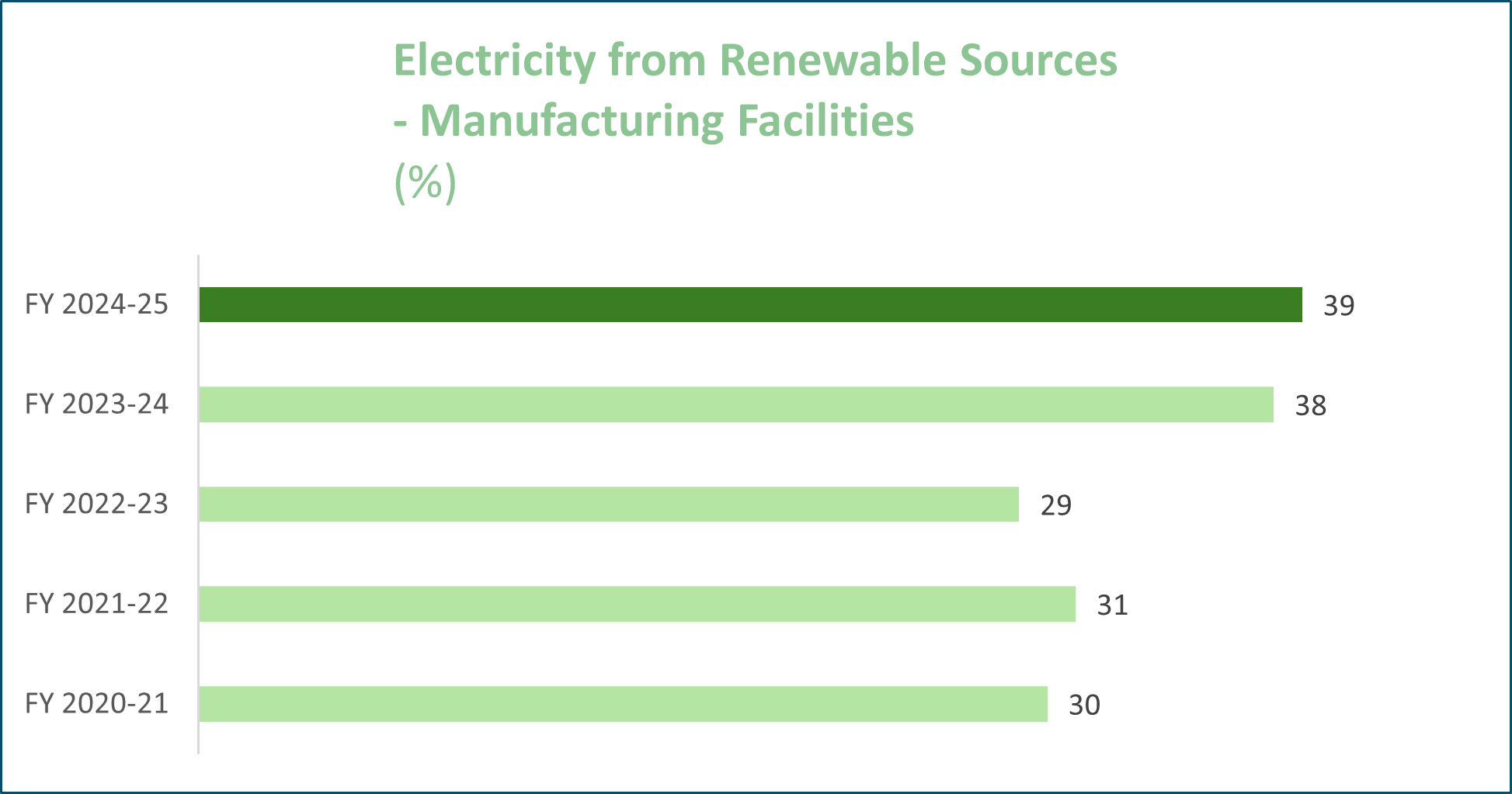

At KNPL, we measure our energy management progress using key performance indicators (KPIs), such as specific power consumption, specific fuel consumption, capacity addition of green power, percentage of green power utilisation, power factor controls, fuel mapping and adoption of greener alternatives.

- 45% of Energy consumption is through renewable sources

- Utilised 39% of electricity from Renewable Sources

Diversification of Energy-mix

Wind Capacity augmentation

Commissioned 2100 KW Wind turbine at Sayakha Plant

Total Captive windmill capacity increased to 8400 KW

Solar Capacity Augmentation

Commissioning work in progress for 3000 KW offsite Captive Solar farm in Yavatmal district in Maharashtra

Renewable Energy:

We constantly search for alternate sources to increase our share of green energy and accordingly plan our initiatives based on feasibility and applicability. This, in turn, allows our facilities to be increasingly self-reliant in their energy needs and thereby reduce the carbon footprint.

In FY 24-25, total renewable energy consumed was 2,67,456 GJ, accounting for 49% of our Company’s total energy consumption.

We are committed to steadily advancing towards achieving our RE 70 targets on a Company-wide scale.

|

|

Heat and Steam generation through Biomass based Boiler

| Heat and Steam generation through Biomass based Boiler | |

|---|---|

| Total Steam Consumption | 19,696 MT |

| Total Heat Consumption | 1,71,489 Lakhs Kcal |

Other Initiatives

• Implementation of Heat recovery system in compressor

• Implementation of fuel catalyst to improve efficiency

• Merging of chillers and compressed air systems

• Implementation of Pump Coatings for reduction of frictional losses on high-capacity Centrifugal Pumps

• Migration to Piped Natural Gas (PNG) at our plants and usage of Fuel catalyst in PNG

• Air Compressor Heat recovery system

• Installation of Air Handling Unit (AHU) blower fans with new energy efficient blowers

• Horizontal Deployment Energy Management System for real time energy tracking, better analysis and identify areas of improvement

ISO 50001 – Energy Management System

At KNPL, energy efficiency is a key environmental priority that drives our commitment to implementing diverse energy-saving initiatives. We continuously seek environmentally responsible and cost-effective solutions to reduce consumption and optimise performance. We remain committed to reducing our energy footprint.

We plan to have all our Plants, Energy Management Systems certified through ISO 50001, an international standard which certifies our commitment towards energy performance and sustainability. Currently, our manufacturing plants at Lote, Hosur and Goindwal are ISO 50001 certified

-

Get in Touch Get in Touch -

Store Locator Store Locator -

Download App Download App

Get in Touch

Looking for something else? Drop your query and we will contact you.