Application Details

Application Details

Surface Condition & Preparation and Joint/Groove Filling

The degree of success and longevity of the floor coating system depends largely on the prevailing floor condition and surface preparation.

A sound, clean and dry concrete substrate is absolutely essential in ensuring maximum bonding between the substrate and flooring system. New concrete surface must be a minimum of 20 days old, free from curing compounds and sealers, free from moisture vapour release and have a moisture content of less than 5% prior to application of the primer. Old concrete surface should ideally be free from dampness and rising moisture, deep oil contaminations and thermoplastic coatings.

For removal of Oily impurities on floor necessary chemical/solvent cleaning or flame cleaning is carried out to have surface free from oil suited for application of primer coat but inspection to be carried for such oily floor before paint system recommendations and applications.

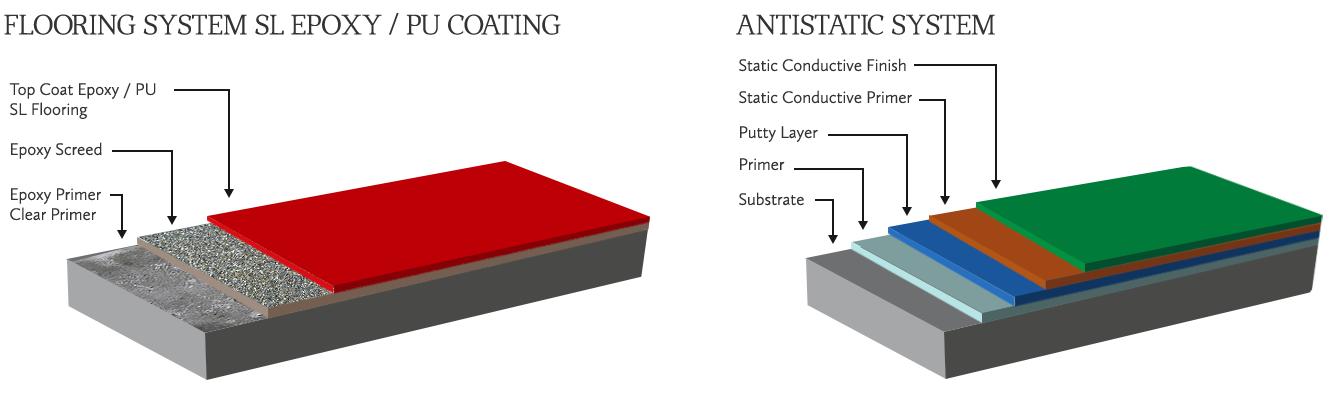

Primer Coat: Ensure that the surface is free from dust , sand and dry suitable for application of first coat of Epoxy Primer coat over the prepared floor and then allow it to dry.

Epoxy Screed Layer: After the prime coat is dry an Epoxy Screed layer of required thickness as per recommended Floor Paint system is applied.

Soft Grinding: Necessary Soft Grinding process is followed to have even smooth levelling and to remove loose coating material of Screed layer for better finish of topcoat.

Sealer Coat or Top Coat: After the floor is soft grinded and cleaned (free from dust generated during grinding). The sealer coat or final recommended top coat of recommended thickness is applied and then allowed to dry for minimum 24 hours.

-

Get in Touch Get in Touch -

Store Locator Store Locator -

Download App Download App

Get in Touch

Looking for something else? Drop your query and we will contact you.