Waterproofing Chemicals for Roofs: Process, Benefits and Safety

Published: 05 Sep 2023 | Modified: 11 Sep 2025

Create Your Dream Home With Our Painting Experts

Fill the form below to book a free site evaluation by Nerolac Nxtgen painting Services expert

Making a structure water-resistant through the process of waterproofing helps to lower indoor humidity levels and minimises damage from water exposure. Using the right waterproofing chemical for concrete and cement constructions is equally vital to ensuring the structural longevity of the property. As a result, we have put together a list of the top waterproofing products and chemicals that can help you use the right waterproofing method for your spaces.

1. Introduction To Waterproof Chemicals

Waterproofing chemicals are like superheroes for our products and properties, shielding them from water's sneaky attempts to cause trouble. Think of them as magical mixtures, carefully crafted to stand guard against leaks and make sure our things last longer. They team up with materials like cement, plastics, colours, and paints, turning them into a powerful force against water damage. Meet the stars of the show: polyethylene, polyurethanes, polysulfide sealants, elastomeric coatings, and acrylic polymers. These champs are known for their water-repelling abilities and can be used in cool ways like making special membranes, adding coatings, or even becoming an integral part of materials. Imagine membranes that act like invisible shields, stopping water from sneaking in. Coatings are like superhero suits for surfaces, making them invincible to water's tricks. And then there are integral systems, where these special chemicals become part of the team, making materials naturally water-resistant. So, the next time you see a strong building or a long-lasting paint job, remember that behind the scenes, waterproofing chemicals are working their magic to keep everything safe and sound.

2. Benefits of Using Waterproof Chemicals

Using waterproofing compounds offers a range of significant benefits, especially when it comes to protecting areas like terraces. You may be sure of excellent results when you search for the best waterproofing chemical for your patio. Here are some reasons why using the proper waterproofing compound can really make a difference:

-

Long-Lasting Protection :

Long-Lasting Protection The right waterproofing compound acts as a shield, preventing water from seeping into the structure. This ensures that your patio is protected for a considerable amount of time against water-related harm.

-

Enhancing Durability :

Enhancing Durability Your terrace's durability is increased when the best waterproofing agent is applied on it. The compound creates a strong barrier that protects the terrace from the elements and daily wear and tear.

-

Leak Prevention :

Leak Prevention Waterproofing compounds are designed to seal cracks and gaps effectively. As a result, your terrace will stay dry and free from water intrusion during rainy seasons.

-

Reduced Maintenance Cost :

Reduced Maintenance Cost Waterproofing solutions reduce the frequency of repairs and maintenance by minimising water damage and leaks. Long-term cost savings result from this.

-

Resistance to Mould and Mildew

Resistance to Mould and Mildew Water intrusion can result in the growth of mould and mildew, which can be dangerous to human health and destructive to the structure. These problems are less likely to happen in an environment created by waterproofing materials.

3. How to Choose the Right Waterproof Chemical for You?

Choosing the right waterproofing chemical, whether for your roof or terrace, involves considering several factors to ensure effective protection and lasting results. Here's a step-by-step guide to help you make the best choice:

-

Assess Your Needs :

Assess Your Needs Begin by evaluating the specific requirements of your project. Are you looking for a waterproofing chemical for a roof or a terrace? Identify the area's exposure to weather conditions, water sources, and potential vulnerabilities.

-

Material Compatibility :

Material Compatibility Check whether the chosen waterproofing compound is compatible with the material of your roof or terrace. Different compounds may work better with specific surfaces, so ensure a harmonious match.

-

Durability :

Durability Prioritise a waterproofing chemical that offers long-lasting protection. Durability is crucial to avoid frequent reapplication and ensure consistent defence against water damage.

-

Application Ease :

Application Ease Evaluate the ease of application. Some compounds require professional installation, while others are DIY-friendly. Choose a solution that aligns with your expertise and resources.

-

Maintenance :

Maintenance Research the maintenance requirements associated with the chosen waterproofing compound. Opt for a solution that demands minimal upkeep, saving you time and effort in the long run.

4. Application Instructions

By following these steps and adhering to the manufacturer's guidelines, you can effectively apply waterproofing chemicals to protect your home from water damage and enhance its longevity. Keep in mind that proper surface preparation, application technique, and attention to detail are essential for successful waterproofing.

-

Read Instructions and Understand the Guidelines from the Manufacturer :

Read Instructions and Understand the Guidelines from the Manufacturer Carefully go through the instructions provided on the label or packaging of your chosen waterproofing chemical. It's essential to grasp the manufacturer's recommendations and specifications to ensure the most effective application for your specific needs.

-

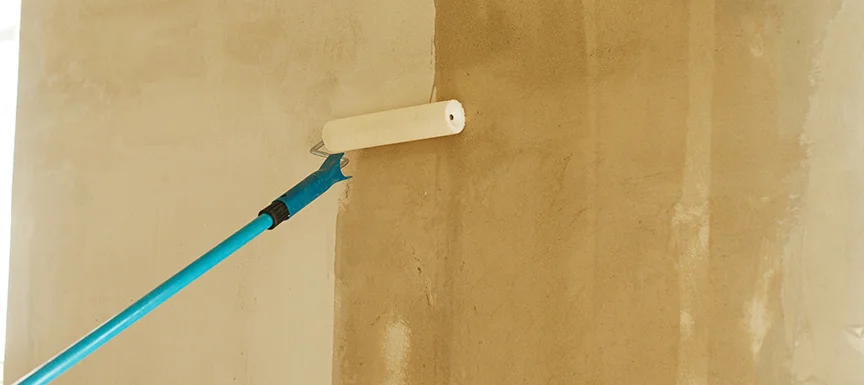

Priming (If Required) for Enhanced Adhesion :

Priming (If Required) for Enhanced Adhesion In some cases, particular waterproofing chemicals might work better with a primer. The primer acts as a bridge, enhancing the bond between the surface and the waterproofing chemical. Adhere to the manufacturer's guidelines for primer application. After applying the primer, allow it to dry completely according to the specified time frame before moving on.

-

Mixing (If Applicable) as Per Manufacturer's Ratios :

Mixing (If Applicable) as Per Manufacturer's Ratios If your selected waterproofing chemical requires mixing, make sure to follow the mixing ratios provided by the manufacturer. Proper mixing ensures the uniform dispersion of essential components, which contributes to the compound's overall performance. Use the recommended tools and techniques for accurate mixing.

-

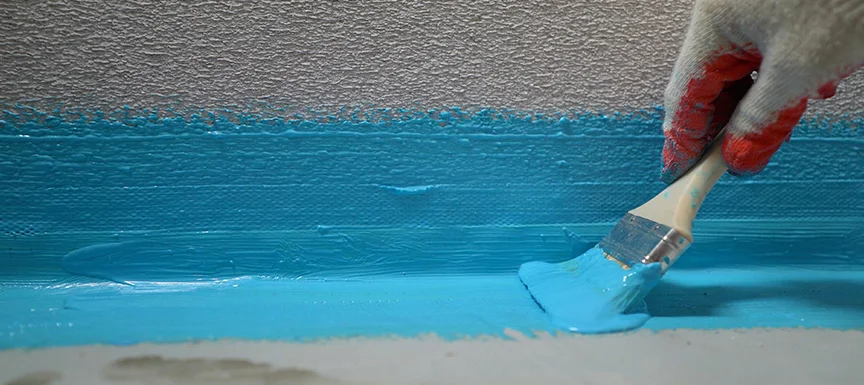

Choose the Right Application Method for Your Surface :

Choose the Right Application Method for Your Surface Different surfaces may require different application methods to achieve the best results. Whether it's brushing, rolling, or spraying, choose the method that suits your surface type and the manufacturer's suggestions. This tailored approach ensures the even distribution of the waterproofing chemical, optimising its protective capabilities.

-

Achieving the Correct Coat Thickness for Maximum Effectiveness :

Achieving the Correct Coat Thickness for Maximum Effectiveness The thickness of the applied waterproofing chemical layer is crucial for its efficiency. Follow the manufacturer's guidelines to apply the recommended coat thickness. This ensures that the chemical forms a robust barrier against water intrusion while maintaining its integrity during the drying process.

-

Ensuring Proper Overlap for Multiple Coats :

Ensuring Proper Overlap for Multiple Coats If you're applying multiple coats of the waterproofing chemical, maintain proper overlap between each coat. Overlapping guarantees that no gaps are left uncovered, providing comprehensive protection against moisture and leaks. Refer to the manufacturer's directions to determine the suitable overlap measurement.

By following each step of the application process with great care and paying close attention to the manufacturer's advice, you're setting the stage for your waterproofing chemical to work its magic. Think of it as a recipe: when you follow each instruction precisely, you end up with a dish that's truly delicious.

Also Read: Protect Your Home With These Waterproofing Methods & Solutions

5. Safety Precautions When Applying Waterproof Chemicals

Here are the safety precautions for applying waterproofing chemicals:

-

Utilise Protective Gear :

Utilise Protective Gear Prioritise your safety by employing the necessary protective gear, including gloves, safety goggles, a mask, and appropriate attire. This safeguards your skin, eyes, and respiratory system from potential interaction with the waterproofing chemicals.

-

Work in a Well-Ventilated Space :

Work in a Well-Ventilated Space Ensure sufficient ventilation in the area where you are working with the waterproofing chemicals. Adequate airflow aids in dispersing any emitted fumes or vapours during the application process. In indoor settings, consider employing fans or opening windows and doors to uphold the circulation of air.

-

Familiarise Yourself with Manufacturer's Guidelines :

Thoroughly acquaint yourself with the manufacturer's safety instructions and guidelines provided on the product's label or packaging. These instructions offer invaluable insights into safe handling, application techniques, and recommended protective measures.

-

Prevent Skin and Eye Contact :

Prevent Skin and Eye Contact Avert direct contact with the waterproofing chemical by donning gloves and safety goggles. Should skin contact occur inadvertently, cleanse the affected area immediately with water and soap. In the event of the chemical coming into contact with your eyes, rinse them with water for a minimum of 15 minutes and seek medical attention.

6. Maintenance Tips for Keeping Your Home Protected with Waterproof Chemicals

By following these guidelines, you're ensuring that the surfaces treated with the chosen waterproofing chemical or the best waterproofing chemical for your terrace stay robustly protected. This proactive maintenance approach prolongs the efficacy of the waterproofing compound, safeguarding your spaces from potential water-related issues.

-

Regular Inspections

Regular Inspections Perform regular inspections on the surfaces treated with waterproofing chemicals, especially those treated with the best waterproofing chemical for your terrace or the chosen waterproofing compound for your roof. Look for any indications of wear, cracks, or vulnerable spots where water might find its way in. Detecting problems early on is crucial to prevent more severe damage.

-

Prompt Repairs

Prompt Repairs Immediately address any signs of deterioration or damage that you observe. Act promptly to maintain the integrity of the barrier. If cracks or holes are present, patch them up and consider reapplying the waterproofing agents as required. This proactive approach ensures that your chosen waterproofing compound or water proofing chemical remains effective.

-

Clear Drainage System

Clear Drainage System Ensure that your drainage systems are unobstructed and functioning properly. This applies whether you've used the best waterproofing chemical for your terrace waterproofing or a water proofing chemical for your roof. Keep gutters, downspouts, and drainage pathways clear. By doing so, you prevent water accumulation that might compromise the effectiveness of your waterproofing efforts.

-

Timely Reapplication

Timely Reapplication Due to exposure to various weather conditions, the efficacy of waterproof chemicals can diminish over time. Whether you've used the best waterproofing chemical for your terrace or the recommended waterproofing compound for your roof, it's important to stay vigilant. Follow the manufacturer's instructions regarding reapplication to ensure that the protective shield is consistently maintained.

7. Alternatives to Using Waterproof Chemicals

It's crucial to give careful consideration to waterproofing structures as it establishes a formidable shield over foundations, roofs, and walls, effectively guarding against water intrusion. Let's delve into some common materials utilised for waterproofing in construction.

-

Cementitious Waterproofing

Cementitious Waterproofing This approach is notably straightforward as the necessary materials are readily available from suppliers dealing with masonry products. Additionally, they're easily mixed and applied within interior wet areas like bathrooms. It's worth noting that this method doesn't undergo contraction and expansion due to its lack of exposure to weathering and sunlight. Cementitious waterproofing finds utility in scenarios such as waterproof deck coatings for bridges, dams, sewage and water treatment plants, and tunnels.

-

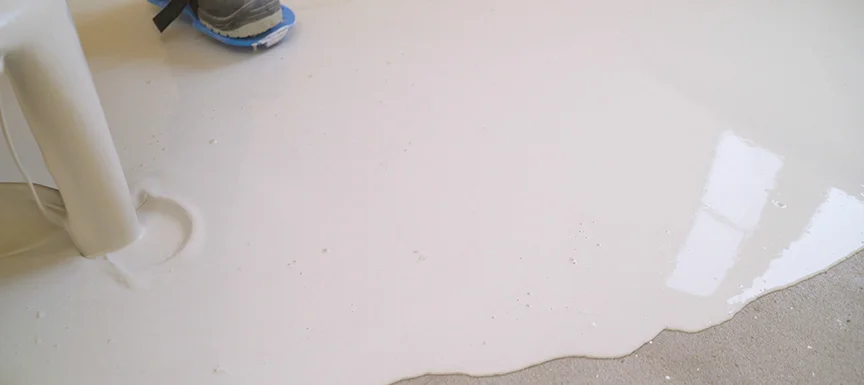

Liquid Waterproofing Membrane

Liquid Waterproofing Membrane This type of coating involves a primer coat and a couple of top coats applied via methods like rolling, spraying, or troweling. Unlike cementitious waterproofing, this offers heightened flexibility. Upon curing, it transforms into a rubbery coating on surfaces. In fact, the elongation properties of this method can reach up to 280 percent, contingent upon the type of polymer employed for the liquid waterproofing.

-

Bituminous Coating Waterproofing

Bituminous Coating Waterproofing Employing bituminous coating offers another avenue for waterproofing structures. Its polymer grade and reinforcement with fibres confer flexibility and water resistance. Commonly referred to as asphalt coating, it performs exceptionally well on concrete foundations. Nevertheless, it's important to note that the bitumen-based components of this coating might become less suitable when exposed to sunlight over time. Flexibility can be enhanced by incorporating more adaptable materials like acrylic or polyurethane-based polymers.

-

Bituminous Membrane Waterproofing

Bituminous Membrane Waterproofing Opting for a waterproof deck coating leads to the consideration of this method, which has proven its mettle for low-sloped roofs due to its reliable performance. It's self-adhesive by virtue of its asphalt, filler, and polymer composition. Certain oils and resins are also added to augment adhesion. This type encompasses both covered and exposed torch-on membranes. The latter is capable of withstanding weathering-related wear and tear due to its mineral granular aggregate.

-

Polyurethane Liquid Membrane Waterproofing

Polyurethane Liquid Membrane Waterproofing Another avenue in waterproofing is the application of polyurethane liquid membrane, albeit being a relatively higher-cost option. It's typically employed in flat roof areas and those subject to weather exposure. Nonetheless, this type of waterproofing offers significant flexibility, though polyurethane can be sensitive to moisture content. Hence, it's vital to assess the moisture content of the concrete slab prior to application. Failure to do so might lead to the membranes experiencing debonding or peeling over time.

In a comprehensive manner, these methods cover a range of areas requiring waterproofing, from bathrooms and kitchens to basements, balconies, decks, green roofs, swimming pools, walls, and water tanks, among others. Therefore, a suitable waterproofing method can be determined based on the specific context. It's also advisable to consult professionals to ensure that the chosen approach aligns with best practices.

Also Read: Choose The Best Waterproofing Materials For Your House

8. Different Applications for Each Type of Chemical

Here are the different applications for each of the waterproofing chemicals mentioned:

Certainly, here are the different applications for each of the waterproofing chemicals mentioned without the keyword focus:

-

Cementitious Waterproofing

Cementitious Waterproofing Cementitious waterproofing is commonly used to protect internal wet areas like bathrooms and toilets. It can be applied on surfaces such as walls and floors to prevent water penetration.

-

Liquid Waterproofing Membrane

Liquid Waterproofing Membrane Liquid waterproofing membrane is versatile and can be applied to various surfaces, including roofs, balconies, and walls. It is often used in both residential and commercial buildings for its flexibility and ability to form a rubbery coating.

-

Bituminous Coating Waterproofing

Bituminous Coating Waterproofing Bituminous coating waterproofing is commonly used for concrete foundations due to its water resistance and flexibility. It is applied on surfaces to create a protective layer against water intrusion.

-

Bituminous Membrane Waterproofing

Bituminous membrane waterproofing is often applied to low-sloped roofs. It is used in areas where reliable water resistance is crucial, such as flat roofs and low-sloped structures.

-

Polyurethane Liquid Membrane Waterproofing

Polyurethane Liquid Membrane Waterproofing Polyurethane liquid membrane waterproofing is commonly used on flat roof areas exposed to weathering. It provides flexibility and is used where long-lasting water protection is required.

Remember that the choice of waterproofing chemical and its application should be based on the specific requirements and characteristics of the project or structure you are working on.

Also Read: Liquid Waterproofing: A Monsoon Season Guide to Safeguard Your House

9. Conclusion

Throughout this blog, the true importance of waterproofing chemicals in shielding structures from water's reach has become crystal clear. These invaluable solutions, with their diverse materials and techniques, play a vital role in fortifying foundations, roofs, and walls, ensuring resilience in the face of moisture-related issues. From the easy accessibility of cementitious waterproofing, perfect for keeping internal wet areas safe, to the adaptability of liquid waterproofing membrane, which offers both flexibility and protection on various surfaces, each approach brings something special to the table. Bituminous coating waterproofing and bituminous membrane waterproofing have shown themselves as strong contenders, excelling in distinct areas – the former in concrete foundations and the latter as a reliable choice for low-sloped roofs.

While the polyurethane liquid membrane may carry a higher cost, it provides unmatched flexibility for flat roofs exposed to the elements. The diversity and specificity of these techniques underscore the tailored approach needed to tackle the unique requirements of different settings and structures. As we look back on the exploration of waterproofing choices and considerations, it's clear that selecting the best waterproofing chemical for a terrace or the right waterproofing compound for a roof depends on a thorough assessment. Truly grasping the strengths and limitations of each method leads to the best outcomes. In the grand scheme of things, waterproofing chemicals remain essential players in the endurance and strength of buildings. By choosing the appropriate waterproofing chemical that suits the specific needs of your project – whether it's for a terrace, roof, or any other critical area – you're contributing to creating spaces that can confidently face water-related challenges. The power of the best waterproofing chemical isn't just about protection; it's about the reassurance that comes from knowing you've proactively shielded your investments and spaces for the long haul.

Nerolac Paints, a leading paint company in India offers a wide range of wall paint colours & painting services & solutions for homes & offices.

-

Best Colour Combination For Walls To Elevate Your Home Interiors Best Colour Combination For Walls To Elevate Your Home Interiors

Intoduction:In 2025, harmonious colour schemes for individuality and…

-

Best Green Colour Combinations for Walls – Schemes & Design Ideas Best Green Colour Combinations for Walls – Schemes & Design Ideas

Introduction:Green has long been a favourite choice in home decor…

-

What Colours Match with Blue? 14 Colour Combinations with Blue for Your Home What Colours Match with Blue? 14 Colour Combinations with Blue for Your Home

Blue is a universally popular colour for décor and design; choosing a colour…

-

Recent Blogs

- What Is the Haldi Ceremony? Meaning, Decoration & Colour Guide

- What Is the Best Haldi Decoration for Home & Weddings?

- What Is the Mehndi Ceremony? Meaning, Colours & Bridal Mehendi Guide

- Vibrant Diwali Decoration Ideas for Living Room, Pooja Room & Balcony

- Diwali Wall Painting Ideas – Easy Art & Colour Designs

-

Get in Touch

Looking for something else? Drop your query and we will contact you.

Next Steps?

-

Pick Your Colour

Want to know which colours will look good on your walls? Use Nerolac’s Colour Palette and get colour combinations of your choice in seconds.

-

Find a Paint Shop Near Your Location

Looking for “paint shop near me”? With Nerolac Store Locator you can find a paint store nearest to your location in seconds!

-

Discover Trending Wall Designs

Warm or cool, loud or subtle, fiery or earthy, whatever be your choice, we have what you want.

-

Explore Nxtgen Painting Services

One-Stop “home Painting Solutions” by Nerolac - Transform your space from Ordinary to Extraordinary.

-

Pastel Colours: The Ultimate Guide to Shades, Palettes & Home Decor Previous Blog Pastel Colours: The Ultimate Guide to Shades, Palettes & Home Decor -

What are the Best Waterproofing Materials? All Types, Uses and Features Next Blog What are the Best Waterproofing Materials? All Types, Uses and Features

Get in Touch

Looking for something else? Drop your query and we will contact you.

Latest Happenings in the Paint World

Get some inspiration from these trending articles

What Is the Haldi Ceremony? Meaning, Decoration & Colour Guide

What Is the Best Haldi Decoration for Home & Weddings?

What Is the Mehndi Ceremony? Meaning, Colours & Bridal Mehendi Guide

Vibrant Diwali Decoration Ideas for Living Room, Pooja Room & Balcony

Diwali Wall Painting Ideas – Easy Art & Colour Designs

Festive Home Paint Colours: Transforming Your Walls and Décor

Popular Searches

- Painting Services

- Wall Paint

- Waterproofing Services

- Enamel Paints

- Wood Paints

- Paint Colour Chart

- Paint Stores

- Two Colour Combination

- Texture Paints

- Wall Painting Designs

- Interior Wall Colour Design

- Wood Wall Décor Ideas

- Window Design Ideas

- Texture Design Ideas

- Puja Room Design Ideas

- Painting Colour Shades

- Office Space Design Ideas

- Mural Wall Paint Design

- Living Room Interior Design

- Kitchen Design Ideas

- Kerala House Design

- Accent Wall Design

- Home Décor Ideas

- Home Colour Combination Ideas

- Hall Design Ideas

- Geometric Wall Design Ideas

- Gate Colour Design

- Festival Painting Ideas

- Exterior Wall Colour Design

- Door Colour Design Ideas

- Bedroom Design Ideas

You will be redirected to a webpage/domain hosted by a third-party service provider (“Service Provider”) for limited purposes related to your interaction with Kansai Nerolac Paints.

Please note that while the Company’s logo may appear on the Service Provider’s page, it is not a Company-controlled page and is operated independently by the Service Provider.

On the Service Provider’s page, you will be provided with options for submitting your data, including uploading documents or providing information through various means.

While these options are enabled through a service provider, the Company does not endorse any specific option, and you are requested to choose independently and at your sole discretion.

Any actions taken on the Service Provider’s page, including the submission of data, shall be a matter between you and the Service Provider, and the Company will not be a party to this relationship.

You are responsible for the consent you provide on the Service Provider’s page, and any acceptance of terms beyond the purpose of use by the Company shall be deemed a contract between you and the Service Provider.

By providing your data through any of the available modes, you agree to share and disclose your information with the Company and the Service Provider for the purposes outlined above.

The Company may process, retain, and use the information as per its discretion.

For any modification, correction or erasure of the provided information, please raise you request by sending an email to [email protected]

-

In this Consent the following capitalized terms shall have the meanings assigned to them hereunder: By 'personal information' we mean names, addresses, email addresses, job experience and history and any other personal information you voluntarily provide about you and your skills and interests .“Data” shall mean all personal data, transactional data, Derivative Data, any other information, etc., in relation to me/us, including the following in relation to past Products:

By providing the consent you agree to providing your personal data which can be used by KNPL for the purposes mentioned hereafter and confirm that this consent is being given freely by you without any pressure, influence, or coercion from any other person, and that the consent is informed and unconditional.

- Information submitted while making any application or request to the KNPL for any Product. Collection of information from personal correspondence (emails, letters) or third-party communications related to user activities on the website. Information may be used to offer products/services from the company and joint sponsors. Communicate with customers about orders, products, services, and promotional offers. Enhance and personalize the shopping and viewing experience on the website.

- Additional information collected during transactions includes billing address, payment instrument details, and tracking information, handling orders, delivering products/services, and processing payments.

- Information from messages or feedback provided by users is collected and retained for dispute resolution and customer support.

- any information obtained/received by KNPL from any other source.

- Collection of demographic and other data for advertising and promotional purposes. It can be used to show relevant content and customer reviews, suggest merchandise and services of interest, Improve the website and prevent/detect fraud or abuse, enable third parties to perform technical or logistical functions on behalf of the company.

- We may share your personal information with vendors or service providers such as companies who help us with database administration. We may also share your personal information with other Kansai Nerolac companies in other countries where data privacy laws may not be equivalent to those in force in India.

- any Derivative Data.

- In connection with the assessment or processing of my application/request for any Requested Product, or to take any steps prior to entering into any contract, or to determine eligibility for the Requested Products, or in connection with the execution or furtherance of a contract/transaction, including performance by the Company or me/us or any other intermediaries, of any contract or part thereof, or any regulatory or legal obligations in relation to any Requested Product availed or in pursuance thereof;

- In connection with the derivation and sharing of any derivative data (between the Company and any processing entity) related to the purposes.

- In connection with contacting me, establishing communication, and monitoring my interactions through email, postal address, telephone, social media, notifications, and other electronic.

- I authorize the Processing Entities to process my Data or any part thereof for any of the Specified Purposes.

- For the purposes covered above, it shall be deemed that I have furnished all the Data separately under this consent.

- I confirm that the Data provided and that will be provided by me from time to time is accurate, updated, and complete in all respects.

- I agree that the consents/authorizations for the Specified Purposes shall survive beyond the validity of such application/tenure of the Product/consummation of any transaction, to the extent any of the Specified Purposes survive.

- The consents given or denied under this document do not limit any other consents obtained or given.

- I acknowledge and confirm that all the Specified Purposes are lawful purposes.

- I understand and agree that the processing of Data is necessary for the Specified Purposes.

- I acknowledge that the request for consent or my giving of this consent does not limit or prejudice any grounds or bases that the Company or any Processing Entities may have for processing the Data without consent. This consent is in addition to any such grounds or bases. For clarity, even if this consent is withdrawn, the Company and/or the Processing Entities may continue to process the Data for the performance of contracts related to the Requested Products or for taking any steps pursuant to the contract or for protecting the legitimate interests of the Company.

- I acknowledge that since this consent is the basis for the Company to enter a contract related to the Requested Products, it is necessary to process the Data for the purposes of the contract. Withdrawal of this consent will not prevent the Company and/or Processing Entities from continuing to process the Data for the purposes of the contract.

DEFINITIONS

“Derivative Data” shall mean any insights, analytics, performance metrics, behavioural projections, customer profiling, and reports (prepared by the Company internally or by third parties) that are generated through the analysis of data collected from customers, sales transactions, market research, and other relevant sources. This includes, but is not limited to, colour preference trends, purchase frequency, customer demographics, product usage patterns, and feedback analysis. Derivative Data may also include predictive analytics regarding future buying behaviour, inventory optimization, and market demand forecasts, whether derived from the information collected from customers or in combination with any other information sourced from external databases, market research firms, or other entities, whether by the Company or other persons. The process of arriving at and generating such Derivative Data through any of the above sub-processes/methods shall be referred to as “Derivation”.

“Specified Purposes” shall collectively mean the collection of personal data for various essential functions, including customer identification and verification to ensure eligibility for services or promotions, processing and fulfilling orders accurately, and enhancing customer engagement through tailored marketing campaigns and personalized offers. The data will also be utilized for monitoring sales trends and inventory management to optimize stock availability, providing customer support and service to address inquiries and resolve issues, and gathering feedback for product improvement and innovation. Additionally, the company will conduct market research and analysis to understand trends and customer preferences, implement risk assessment measures to detect and prevent fraud, and ensure compliance with legal obligations, including data protection and consumer rights. Personal data will support the management of loyalty programs and promotions, enhance the digital experience on the website through personalization, and facilitate data sharing with third-party partners for operational efficiency. Furthermore, the company will collect data for sustainability and environmental reporting, engage in necessary legal and regulatory compliance activities, and utilize analytics to monitor website performance and overall business effectiveness. aggregators, payment gateways, payments systems, performance of any legal and/or regulatory obligations, filings, reporting, etc., whether any of these are undertaken internally or through any Processing Entity.

"Processing” shall mean any operation or set of operations performed on Data, and includes operations such as collection, recording, organisation, structuring, storage, adaptation, retrieval, use, alignment or combination, indexing, sharing, disclosure by transmission, dissemination or otherwise making available, restriction, erasure or destruction and the term “Process” and “Processed” shall be construed accordingly.

“Processing Entity” shall mean any third party company(ies), bureau(s), consultant(s), vendor(s), agent(s), fintech entity(ies), co-brand entity(ies)/partner(s), distributor(s), selling/ marketing agent(s), any partner(s), collaborator(s), merchant(s), aggregator(s), lead generator(s), sourcing entity(ies), client(s), customer(s) or other person(s) with whom the KNPL has any direct or indirect arrangement or tie-up or contract for any products or services/ intermediary(ies) in any ecosystem of which KNPL is a part, and such Processing Entities’ service providers, consultants, vendors, etc.

“Product(s)” shall mean all types of paint and related products offered by the Company, including but not limited to topcoat, under coat, interior and exterior paints, primers, sealants, varnishes, specialty coatings, tools and ancillaries, wood finishes and construction chemicals. This definition encompasses products sold directly through the Company’s online platform, as well as those distributed through authorized dealers, retailers, contractors or other third-party vendors. The Products may also include complementary items such as paintbrushes, rollers, paint trays, and other application tools, as well as services related to colour consultation, custom mixing, and professional painting services. The Products that have been applied for, requested, or purchased by me/us (including where the initiation of any transaction is not directly with the Company but is with a relevant distributor or retailer) shall be referred to as “Requested Products,” while any Products (including future offerings) other than the Requested Products shall be referred to as “Other Products.”

CONSENT

I hereby authorize Kansai Nerolac Paints Limited (“Company”) to process my personal data (“Data”) or any part thereof for any of the Specified Purposes:

-

SPECIFIED PURPOSE

-

PURPOSES

-

Get in Touch Get in Touch -

Store Locator Store Locator -

Download App Download App

Get in Touch

Looking for something else? Drop your query and we will contact you.